Industrial rubber and plastics is hardly the most attention grabbing of subjects on the surface of it. Our associations with rubber are generally limited to the interactions we have with rubber in the course of our day to day lives and as these instances are neither multitudinous nor particularly remarkable: it is rare that you’ll ever encounter someone with a particular vociferous or well informed view of rubber, industrial rubber or its manufacture. There is however an incredibly interesting side to not just the manufacture of rubber but more so the array of often unseen applications to which it lends itself: in fact, industrial rubber is an incredibly important material in the facilitation of numerous processes, the results of which we take for granted.

Industrial rubber and plastics is hardly the most attention grabbing of subjects on the surface of it. Our associations with rubber are generally limited to the interactions we have with rubber in the course of our day to day lives and as these instances are neither multitudinous nor particularly remarkable: it is rare that you’ll ever encounter someone with a particular vociferous or well informed view of rubber, industrial rubber or its manufacture. There is however an incredibly interesting side to not just the manufacture of rubber but more so the array of often unseen applications to which it lends itself: in fact, industrial rubber is an incredibly important material in the facilitation of numerous processes, the results of which we take for granted.

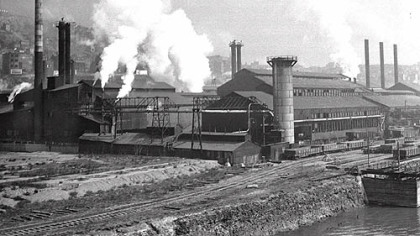

Amongst the most common uses for industrial rubber is the manufacture of seals. Seals are on the whole relatively simple pieces of equipment which serve to help ensure that equipment is water or airtight as appropriate. Achieving a tight and reliable seal is imperative in a number of industries. In the food and drinks Businesses With Low Barriers To Entry for instance, rubber seals are required for dosing machines, filling machines and as part of the canning process. Strong rubber seals are also instrumental in waste water treatment both in hydraulic systems and to prevent leakage at pipe joins- something which is particularly important when sewage is involved! In Steel and heavy industries, amongst the multiple applications of seals are test tube stoppers and large diameter seals for manufacturing.

As well as the somewhat obvious use of rubber in the manufacture of industrial seals, it is also used for items which are used directly by the end-user. From walking stick ferrules, to rubber foot pedals and doorstops- rubber is to be found in multitudinous guises throughout the home and is even more widely utilised in the construction of automobiles: the mats and pedals in the cabin wells, seals in the engine and all instances of rubber foam throughout the vehicle being just a sample of the uses.

Plastic is just as prevalent in Manufacturing Industry Overview and manufacture. PVC in particular is treated with plasticizers in order to improve flexibility and then used for such equipment as strip curtains, hoses and ducting. PVC hose used in conjunction with rubber seals is an absolutely essential component in numerous forms of industrial and agricultural machinery: not to mention the vital role it plays in the food and beverage industry and the myriad tasks this combination is used for in the consumer market. The uses of industrial rubber and plastic are so extensive and far reaching that it is harder to name an industry that doesn?t make use of them than to recall one that does. They may not be the most fascinating thing to discuss but are at the foundation of limitless process and objects which shape our modern society.